In this interview, Talia Levy, Associate Scientist at the Cell and Gene Therapy Catapult (CGT Catapult), highlights one of our research projects involving the development of a continuous manufacturing strategy for rAAV therapies.

1. Please provide an overview of the project presented in this poster

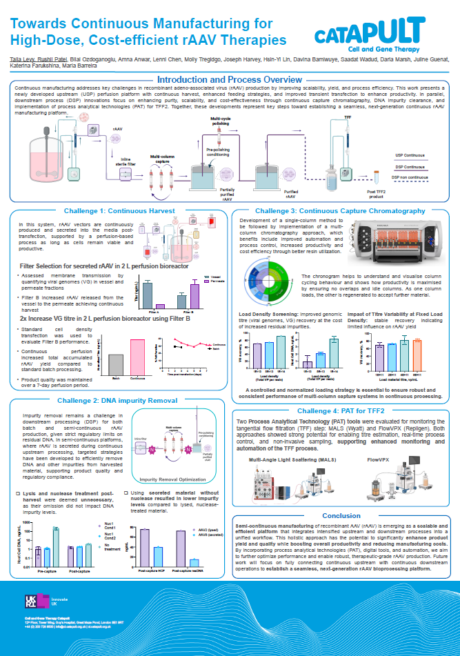

This project focuses on developing a continuous manufacturing strategy for high-dose, cost-efficient recombinant adeno-associated virus (rAAV) therapies. Traditional batch-based rAAV production faces significant challenges, particularly around scalability, cost, and process consistency, which can limit accessibility to patients who need high-dose gene therapies.

Our approach integrates continuous intensified upstream production with continuous downstream purification to streamline the entire manufacturing workflow. By combining these elements, the project aims to establish a robust, scalable, and automated platform that maintains high product quality while reducing production time and cost.

Ultimately, this work supports the broader goal of enabling large-scale, reproducible, and affordable rAAV manufacturing, paving the way for more widespread access to advanced gene therapy treatments.

Learn more about how we support the development of gene therapies

2. Please describe your role and how you were involved in this project

Working as an Associate Scientist in the downstream processing team, my focus is on developing the multi-column chromatography purification step, a key part of the rAAV development process.

We use a multi-column chromatography platform that enables continuous processing by using several smaller columns instead of a single large batch column. This involves close collaboration with other team members to develop and optimise the multi-column method, with the goal of maintaining both product quality and process efficiency.

Day to day, I support experimental design, run chromatography experiments, analyse and troubleshoot process data to improve system performance. A key part of the role is evaluating how process adjustments affect recovery, purity, and throughput, as well as contributing to technical discussions and documentation that guide ongoing method development.

Being hands-on and seeing how process improvements translate into measurable results has been a particularly motivating part of the work.

3. What do you find most rewarding about working on this project?

The most rewarding part of working on this project is being part of a collaborative and innovative team that is constantly learning and improving new processes.

I have really enjoyed the hands-on technical work and the opportunity to gain a deep understanding of the multi-column chromatography system and use this to develop and implement continuous chromatography methods.

It has been especially fulfilling to see how everyone’s efforts come together to tackle complex challenges and keep the project moving forward.

Being involved in an innovative project that aims to make gene therapy manufacturing more efficient and accessible is highly motivating and makes the experience even more meaningful.

4. What has been the greatest challenge you have experienced and how have you overcome this?

One of the biggest challenges in this project is that a continuous, cost-effective manufacturing process for AAV therapies doesn’t currently exist.

We are working to change that by using a multi-column chromatography system to develop a continuous purification process that’s more efficient, automated, and scalable, with the goal of making high-dose AAV therapies more accessible to patients.

Inherently, the system we are using was originally designed for monoclonal antibody (mAb) production, so we have had to adapt and fine-tune it for AAV purification.

Overcoming these challenges has taken a lot of team collaboration, troubleshooting, and persistence. I have learned to approach each experiment with curiosity and patience, using every run, successful or not, as an opportunity to improve. It has been really great to see the progress we are making and how the process continues to evolve with each step forward.

5. How do you plan to build on the success of this project and establish a seamless, next-generation AAV bioprocessing platform?

Our first experiments have been successful in establishing proof of concept, showing that a continuous capture process for AAV purification is both achievable and promising.

Moving forward, we are focusing on strengthening the process to make it more robust, scalable, and suitable for manufacturing environments. The next step is to further automate process control and integrate it with continuous upstream production, with the long-term goal of creating a fully seamless, end-to-end continuous bioprocess. This could involve linking capture and polishing steps, implementing real-time monitoring tools, and refining control strategies to maintain consistency over extended production runs.

It’s exciting to be part of a project that continues to evolve and push boundaries. Each stage of development brings us closer to a next-generation AAV manufacturing platform that could help improve both the efficiency and accessibility of gene therapies worldwide.

Contact us if you are looking to improve your gene therapy development process