Gene therapies

We are committed to advancing gene therapies and identifying solutions to key challenges including scalability, cost-effectiveness, safety, and regulatory compliance. We support industry and academic partners across the full spectrum of technologies - from viral vectors to non-viral delivery systems, gene editing tools, and in vivo gene therapies - translating your innovations into scalable, GMP-ready solutions.

Our areas of expertise include:

Gene delivery

Our experts provide innovative bioprocessing, formulation, and characterisation solutions to support the development and scalable production of viral vectors for gene delivery.

With a particular focus on recombinant adeno-associated virus (rAAV), we also support other gene delivery platforms including lentiviral vectors and emerging non-viral technologies.

Benefit from our expertise in:

- Increasing viral vector production efficiency and quality

- Production of high yield/high purity viral vector batches

- Viral vector upstream, downstream, and analytical methods

- Viral vector formulation and vial-fill and finish solutions

Cell line development and engineering

We have developed a GMP-ready HEK293 suspension cell line for the robust manufacture of rAAV.

Demonstrating comparable productivity to other lines commercially available, our cell line enables you to improve your rAAV production process with increased operational freedom at reduced cost.

Benefit from:

- Deep characterisation and genetic engineering ability

- Expert recommendations for testing and optimisation

- Established protocols for AAV production

- Clear license structures for onward commercialisation

This platform is available for in-house evaluation and manufacture, and out-sourcing to third party service providers. Contact us if you are interested.

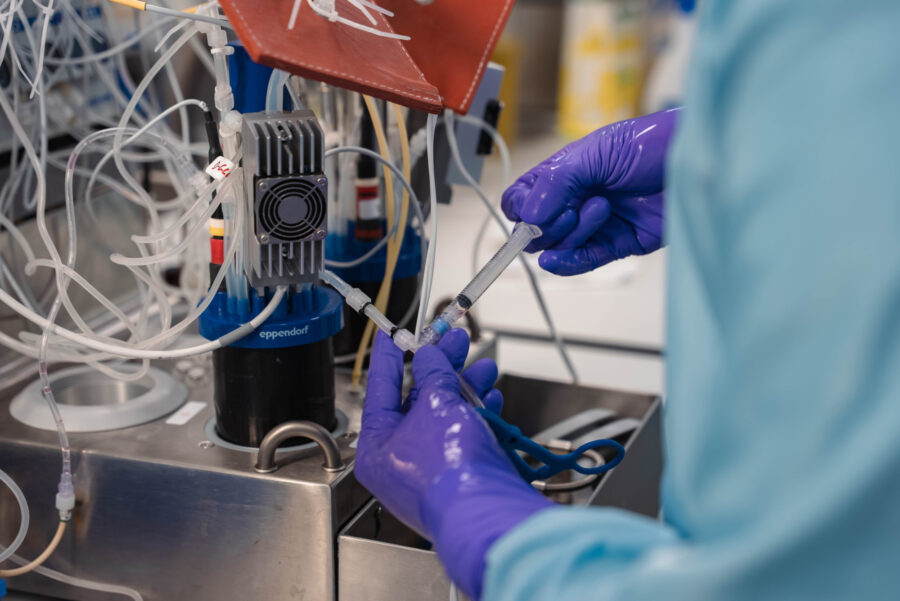

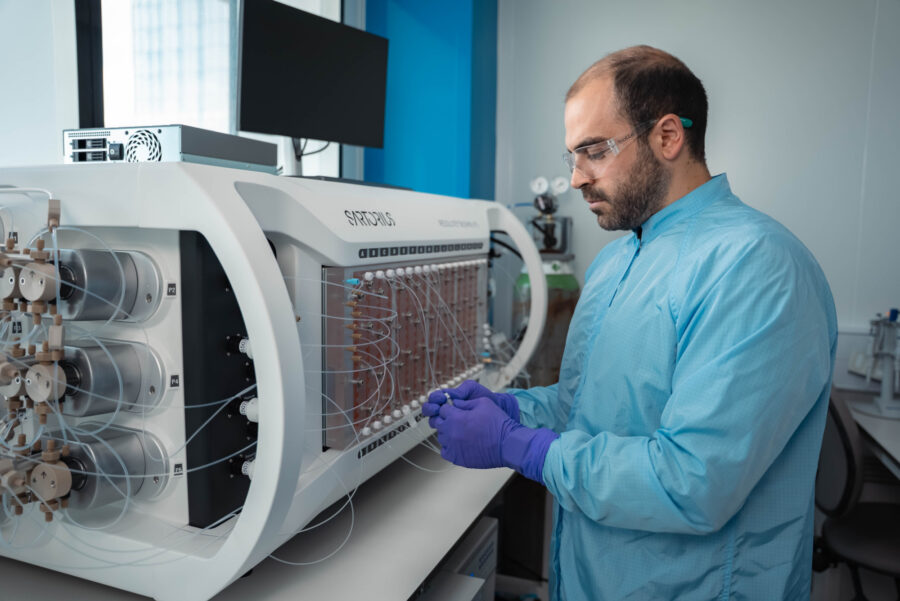

Manufacturing innovation and scale up

Our scalable GMP platform for rAAV production and purification offers robust upstream and downstream processing. We can collaborate with you to optimise and innovate your own viral vector manufacturing processes, combining standard methods with continuous bioprocessing to improve cost-effectiveness and scalability.

Benefit from:

- Scalable GMP production up to 50 litres, with tailored process development and efficient tech transfer to your site

- Real-time in-line monitoring of key rAAV quality attributes

- Advanced lysis and capture for DNA impurity removal

- Digital twin modelling for enhanced process understanding and control

- Continuous bioprocessing solutions to increase efficiency at reduced cost

Analytical development

We have developed in-house analytical assays, tools and bioinformatics solutions to help you leverage genetic insights for increased rAAV platform performance. We can support you to establish your own accurate and precise analytical methods to ensure the efficiency of your rAAV manufacturing process.

Benefit from:

- An analytical platform for rAAV manufacturing to enable effective process characterisation and product release

- Customisable assays tailored to your specific capsid or therapeutic product

- CRISPR-based tools and readouts for target validation

- Robust bioinformatics pipelines for multi-omics analysis

News feed

Working on a cell or gene therapy innovation challenge?

Contact us today to find out how we can support you.